1. Role of Gellan Gum

Low Acyl Gellan Gum has become a key ingredient in the production of solid car air-fresheners due to its remarkable ability to form heat-stable, clear gels that can hold moisture and fragrance under high temperature conditions. As car interiors are subjected to fluctuating temperatures, especially under direct sunlight, it is crucial for the air-freshener to maintain its form and release fragrance steadily. Gellan Gum plays a central role in ensuring these products stay intact, perform well, and deliver a consistent fragrance over time.

The specific benefits of Gellan Gum in solid car air-fresheners include:

Stable Gel Formation: Low Acyl Gellan Gum can form a firm gel network that holds fragrance oils in place. This prevents fragrance evaporation and leakage, keeping the scent fresh for longer periods.

Heat Stability: One of the key advantages of Gellan Gum is its ability to remain stable at higher temperatures. Unlike other gelling agents, Gellan Gum forms gels that do not melt or lose their structure even when exposed to high heat, such as the temperatures inside a car during the summer.

Elasticity and Shock Resistance: The gel produced by Gellan Gum has improved elasticity, making it resilient to vibrations or movements that occur when the vehicle is in motion. This ensures that the air-freshener will retain its form and effectiveness even in a shaking environment, such as in a car.

2. Usage Instructions

Low Acyl Gellan Gum is easy to use and can be easily dispersed into water-based systems with standard mixing equipment. The recommended dosage is:

Gellan Gum dosage: 0.6%–0.8%

Calcium source: Calcium Chloride 0.08% or Calcium Lactate 0.15%

The following outlines the typical process for preparing a solid car air-freshener using Gellan Gum:

Disperse the Gellan Gum: Begin by adding the Gellan Gum (either by itself or mixed with other ingredients such as fragrances or colorants) to cold water. Stir thoroughly to ensure even dispersion. The addition of a chelating agent can improve the solubility of Gellan Gum, making the process smoother.

Heat the Mixture: Heat the water mixture to above 85°C to dissolve the Gellan Gum and activate its gelling properties. During this stage, the Gellan Gum forms a gel-like consistency that will later provide structural integrity to the air-freshener.

Add Calcium: Once the Gellan Gum is dissolved, introduce a calcium source such as Calcium Chloride or Calcium Lactate. These ions help to crosslink the Gellan Gum molecules, leading to a more robust gel formation. This step is critical for improving the gel’s strength and its ability to hold its shape under different conditions.

Cool the Mixture: Allow the mixture to cool down to room temperature. As the gel cools, it will harden and take shape, becoming a solid gel that can hold fragrance oils and other additives. Once the gel has solidified, it will be ready for use in solid air-freshener products.

Incorporate Fragrance: Add fragrance oils to the gel mixture before it sets. The fragrance is encapsulated within the gel, ensuring that it is released gradually over time when the air-freshener is placed in the car.

Final Shaping: The gel can then be molded into the desired shape—whether in small blocks, discs, or other formats suitable for air-fresheners.

3. Common Issues and Solutions

Problem 1: Soft Gel or Melting Under High Temperature

Cause: If the Gellan Gum dosage is insufficient or the calcium content is too low, the gel may not form strongly enough, leading to a product that can soften or melt when exposed to high temperatures inside the car.

Solution: To resolve this issue, increase the Gellan Gum dosage to 0.8% and ensure the calcium ion content is adequate (0.08% Calcium Chloride or 0.15% Calcium Lactate). This will provide stronger gel formation, ensuring the product maintains its shape at elevated temperatures.

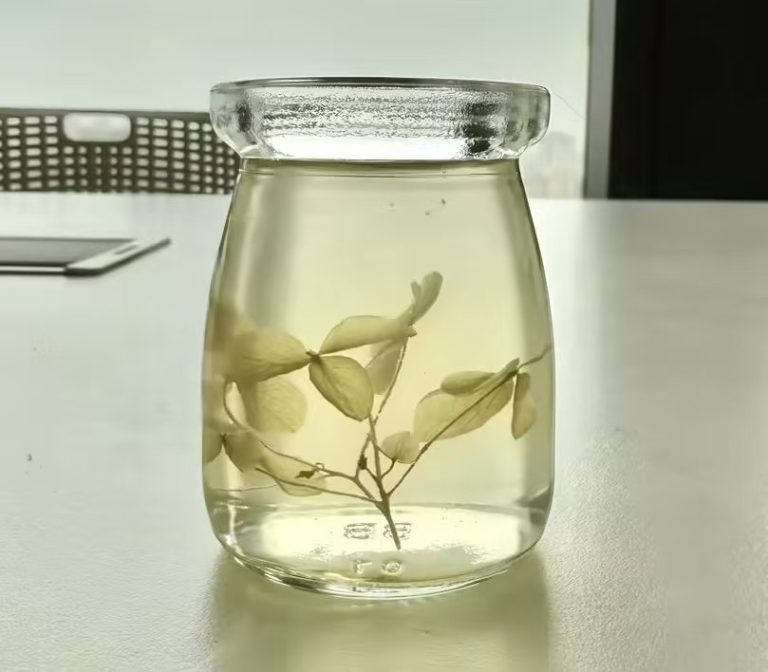

Problem 2: Cloudiness or Lack of Transparency in the Gel

Cause: Cloudiness can occur if the Gellan Gum is not fully dissolved or if the mixture is not heated to the proper temperature (above 85°C).

Solution: Ensure that the mixture is heated to 85°C or above and stirred thoroughly to achieve a smooth, clear gel. The solution should be transparent and free from any air bubbles or particles. If necessary, use a chelation agent to improve the solubility and clarity of the gel.

Problem 3: Cracks or Oil Leakage After Vibration

Cause: The gel may be prone to cracking or leaking fragrance oils if the crosslinking is uneven or the gel lacks sufficient elasticity to resist the shaking motion within the vehicle.

Solution: Optimize the calcium ion addition to improve the gel’s elasticity and resistance to cracking. Increasing the Gellan Gum dosage slightly can also help enhance the gel’s shock resistance and reduce the chances of oil leakage.