Introduction

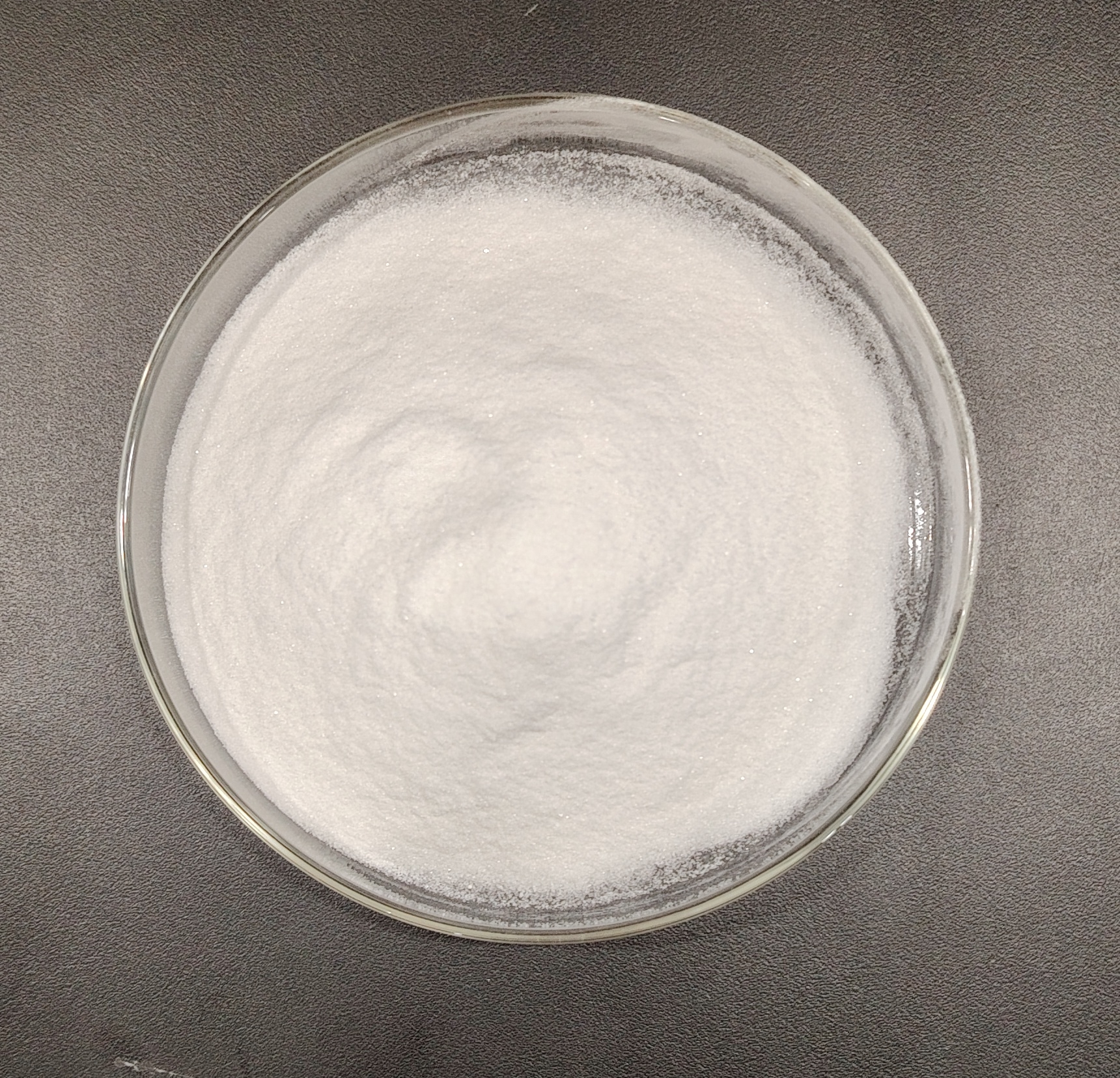

Gellan gum is a polysaccharide hydrocolloid produced by the microorganism Sphingomonas Paucimobilis and Corn Starch with plant origin, under fermentation processing from a carbohydrate source (Edible glucose) and Nitrogen Souce (Plant Protein). Deacylation is carried out by treating the product with alkali. Appearance of Low Acyl Gellan Gum is white fine powder.

Biogum Gellan BJ-GE101N TYPE LA Gellan Gum is targeted for gelling applications in Food, Bakery, Boba Balls, Plant Tissue Culture Media, Solid Air-Freshener, Body lotions, Tooth Paste, Soft/Hard Capsules, Meat Processing.

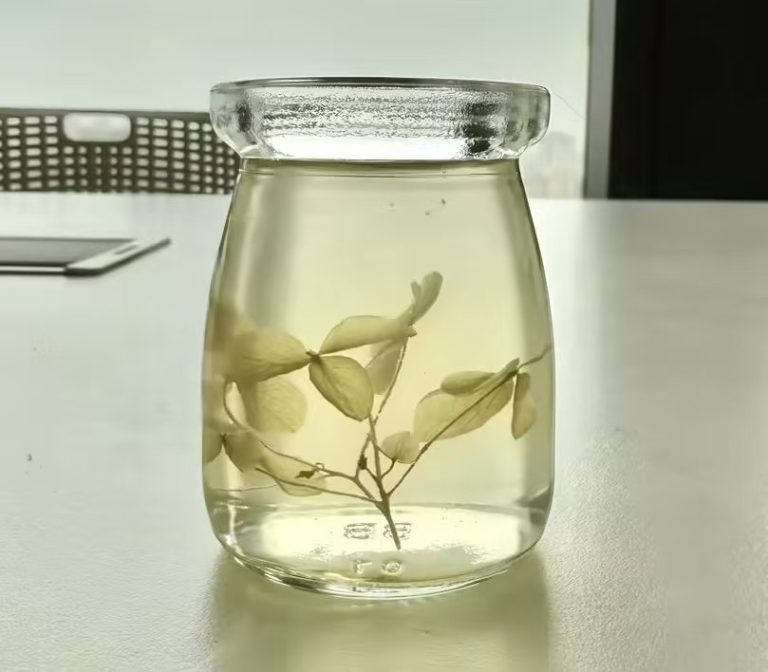

Low Acyl Gellan Gum is helping to form very high transparency and hard gels, but BJ-GE101N Biogum Gellan improved the elasticity of the gels and ensure a stability when combining with carrageening use in gelling conditions.

Gel type gellan gum is a customized low acyl gellan gum with strong gel strength, high transparency, and good synergy with carrageenan, konjac gum, agar, etc. Its state is white powder, with a bright white color and a compact density, which is very easy to disperse and dissolve in water.

In the food industry, as an excellent gel agent, it is mainly used in water-based gel systems such as jelly, jam, candy, milk tea crystal ball, etc., which mainly plays the role of gel forming. The recommended amount is 0.1-0.5%. The gel type gellan gum is a low acyl gellan gum with ultra-high transparency and ultra strong gel strength. The gel formed by it can be thermally irreversible with the help of divalent cations.

In the daily chemical industry, gel type gellan gum is widely used in the production and processing of solid ointment because of its superior gel type energy, water retention performance, thermal stability and other characteristics. The flavor release is long-lasting, without water separation or shrinkage.

Gellan gum can form gel with different texture from elasticity to brittleness, and can control the melting temperature to produce thermal irreversible gel. Therefore, using Gellan gum can produce various forms of jelly and other gel products at very low dosage, especially in the production of multi-color jelly, which is widely used. Multi layer jelly with different colors and flavors can be made by using oil soluble food coloring agents and spices, which can produce colored jelly with various colors and flavors such as red, green, yellow, white, etc., without color mixing or flavor distortion.

Specifications

Gellan Gum Purity:85%-108%;

Assay(CO2 Yielding):3.3%-6.8%

Total Nitrogen: 3%max

Loss on Drying:15%max

Transmittance(0.5% solution):85%min.

Gel Strength(0.5%solution):900g/cm2 min.

pH(1%solution):5.0-8.0

Suspension Test(0.015%solution):Pass.

Applications

Biogum Gellan BJ-GE101N TYPE LA Gellan Gum is targeted for gelling applications in Food, Bakery, Boba Balls, Plant Tissue Culture Media, Solid Air-Freshener, Body lotions, Tooth Paste, Soft/Hard Capsules, Meat Processing.

This type of gellan gum is a low acyl gellan gum with ultra-high transparency and ultra strong gel strength. The gel formed by it can be thermally irreversible with the help of divalent cations.

In the daily chemical industry, gel type gellan gum is widely used in the production and processing of solid ointment because of its superior gel type energy, water retention performance, thermal stability and other characteristics. The flavor release is long-lasting, without water separation or shrinkage.

The recommended amount is 0.1-0.8%.

Advantages

Strong and brittle gel;

High transpancy;

Water retention;

Heat-irreversible;

Good solubility;

Plant Origin Vegan Material

Acid Stable.

Usage

01.

For gelling purposes, the recommended amount is 0.1-0.8%.

02.

Disolving: Gellan Gum dissolve in water with no kations by heating. So Calcium Slats should be added only after dissolving of gellan gum.

03.

Gelifaction : the gels formed under help of ions( Ca++ is heat-irreversible; K+ and Na+ is heat reversible)

04.

Setting Temperature is advised to be below 30℃ or even lower to 23℃